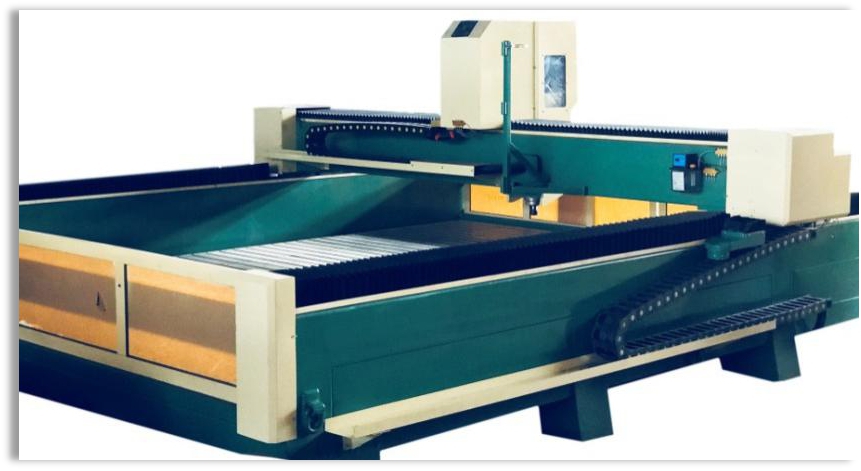

Transformer Insulation parts Processing Center by setting up the program, the graph of any given shape can be cut out on laminated wood or laminated cardboard.It can also process the circular groove and linear groove on the end ring, drill hole and local plane machining.The special requirements of transformer insulation industry should be fully considered in the design and manufacture of this equipment, and special protection should be made in dedusting and preventing metal pollution.

Technical parameter for Transformer Insulation parts Processing Center

|

Effective stroke (mm) Effective stroke (mm) |

1500*3000 |

3300*3300 |

|

Maximum machining Thickness (mm) |

150 |

260 |

|

XY to the fastest empty line speed (m/min) |

12 |

20 |

|

XY to the fastest empty line speed (m/min) XY to the fastest empty line speed (m/min) XY to the fastest empty line speed (m/min) |

3 |

8 |

|

XY direction positioning accuracy (mm) XY direction positioning accuracy (mm) |

0.2 |

0.2 |

|

Z-direction positioning accuracy (mm) |

0.05 |

0.05 |

|

Spindle speed r/min |

0~24000 |

0~18000 |

|

Spindle power KW |

6 |

11 |

|

Workbench |

Aluminum alloy T-slot or vacuum adsorption |

Aluminum alloy T-slot or vacuum adsorption |

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com