Technical parameter for Copper/ Aluminum Extrusion Machine:

| Wheel Diameter | 250mm | 300mm | 550mm |

| Main Motor | 45KW/1000rpm | 90KW/1000rpm | 400KW/1000rpm |

| Rotation Speed | 1-11 rpm | 1-12 rpm | 1-8 rpm |

| Rod Diameter | 8 mm± 0.2 mm | 12.5 mm± 0.5 mm | 22 mm± 0.2 mm |

| Min-Max Cross Sectional Area | 5mm2~70mm2 | 10mm2~250mm2 | 400mm2~6000mm2 |

| Maximum Width | 15 mm | 45 mm | 280 mm (or 90mm rod) |

| Output (average) | 100-200Kg/h | 200-450Kg/h | 2300Kg/h |

Copper Extrusion Machine Equipment composition

Feedstock Pay-off

Feedstock Straightener Unit

Feed-in and Cutting System

Continuous Extrusion Machine (Right Handed Machine)

Water Cooling System

Product Length Counter

Take-up Stand (Type TU-20)

Hydraulic and Lubricate System

300Mpa EHV System

Electric and Computer Control system

We are 5A Class Transformer Home with a full solution for Transformer Industry

1, A real manufacturer with complete in-house facilities

2, A professional R&D Center, having collaboration with well-know Shandong University

3, A top performance company certificated with International Standards like ISO, CE, SGS and BV etc

4, A better cost-efficient supplier , all key components are international brands like Simens, Schneider and Mitsubishi etc.

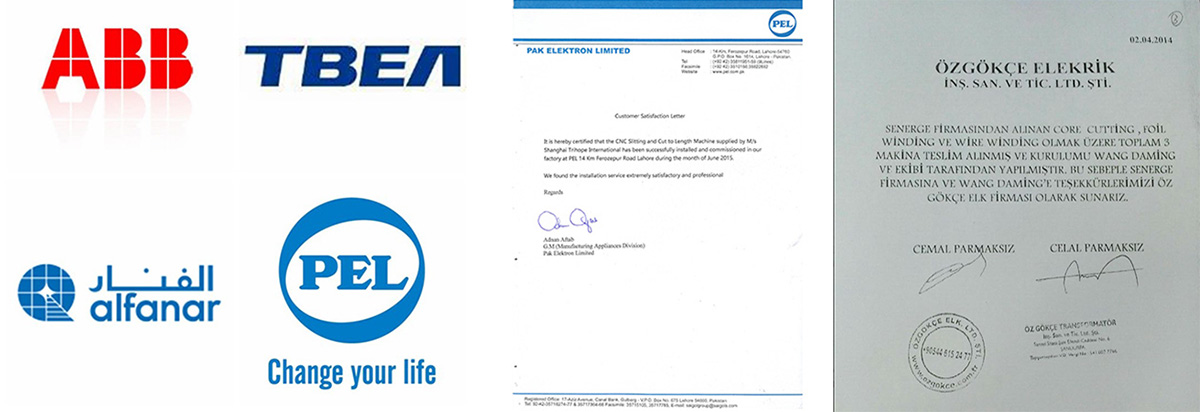

5, A reliable business partner, served for ABB, TBEA, PEL, ALFANAR, ZETRAK etc in past 17 years

Q1: How could we choose the right model Wire Extrusion Machine?

A: You could give us your rod diameter and Min-Max Cross Sectional Area, we will recommend the right model to you.

Q2:How could you manage the bending machine quality?

A: We have the very strictly 6s management system, All departments supervise each other. The spare parts and material used on machinery will be checked before start production. And before delivery, we will installation and commission at home, do a comprehensive inspection

Q3: Can u provide the After-sales installation and commissioning service in our site?

Yes, we have the professional team for after-sales service. We will provide installation manual and video when machine delivery, If you need, we can also delegated engineers to visit your site for installation and commission. We promise we will provide 24 hours of online feedback when you need any help.

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com