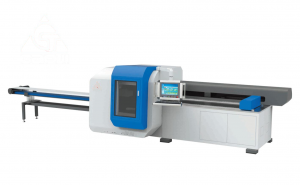

CNC busbar punch and cut machine can finish hole punching (round hole, oblong hole etc), embossing, shearing, grooving, cutting filleted corner etc.

This series machine can match with CNC bender and forn busbar processing production line.

Feature of CNC busbar processing machine :

1.The special aided design software of busbar processing (GJ3D) is connected with the machine and auto program is realized.

2.Human-computer interface, the operation is simple and can demonstrate real-time the operation atatus of the program, the screen can show the alarm information of the machine; it can set the basic die parameters and control the machine operation.

3.High Speed Operation System

High accurate ball screw transmission, coordinated with high accurate straight guide, high precision, fast effective, long service time and no noise.

4.Machine used in thickness≤15mm, width≤200mm, length≤6000mm of copper platoon punched, slot, cut the feet, cutting, pressing process processing.

5.Punching distance precision ±0.2mm, determine the position precision ±0.05mm, repeat positioning accuracy ±0.03mm .

Technical parameter for busbar punching shearing machine:

| Description | Unit | Parameter | |

| Press force | Punching unit | kN | 500 |

| Shearing unit | kN | 500 | |

| Embossing unit | kN | 500 | |

| X max speed | m/min | 60 | |

| X max stroke | mm | 2000 | |

| Y max stroke | mm | 530 | |

| Z max stroke | mm | 350 | |

| Stoke of hit cylinder | mm | 45 | |

| Max hit speed | HPM | 120 ,150 | |

| Tool kit | Punching mould | Set | 6,8 |

| Shearing mould | Set | 1,2 | |

| Embossing unit | Set | 1 | |

| Control axis | 3,5 | ||

| Hole pitch accuracy | mm/m | 0.2 | |

| Max hole punch size | mm | 32(thickness of copper bar:<12mm) | |

| Max embossing area | mm² | 160×60 | |

| Max busbar size (L×W×H) | mm | 6000×200×15 | |

| Total power | kW | 14 | |

| Main machine size (L×W) | mm | 7500×2980 | |

| Machine weight | kg | 7600 | |

We are 5A Class Transformer Home with a full solution for Transformer Industry

1, A real manufacturer with complete in-house facilities

2, A professional R&D Center, having collaboration with well-know Shandong University

3, A top performance company certificated with International Standards like ISO, CE, SGS and BV etc

4, A better cost-efficient supplier , all key components are international brands like Simens, Schneider and Mitsubishi etc.

5, A reliable business partner, served for ABB, TBEA, PEL, ALFANAR, ZETRAK etc in past 17 years

Q1: How could we choose the right model of busbar processing machine?

A: Please give us your detail requirements, Our engineer will finalize which model suitable for you.

Q2: Can you provide the turn-key service of supplying complete machinery and equipment for a new transformer factory ?

A: Yes, we have rich experience for establish a new transformer factory. And had successfully helped Pakistan and Bangladesh customers to build a transformer factory.

Q3: Can u provide the After-sales installation and commissioning service in our site?

Yes, we have the professional team for after-sales service. We will provide installation manual and video when machine delivery, If you need, we can also delegated engineers to visit your site for installation and commission. We promise we will provide 24 hours of online feedback when you need any help.

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com