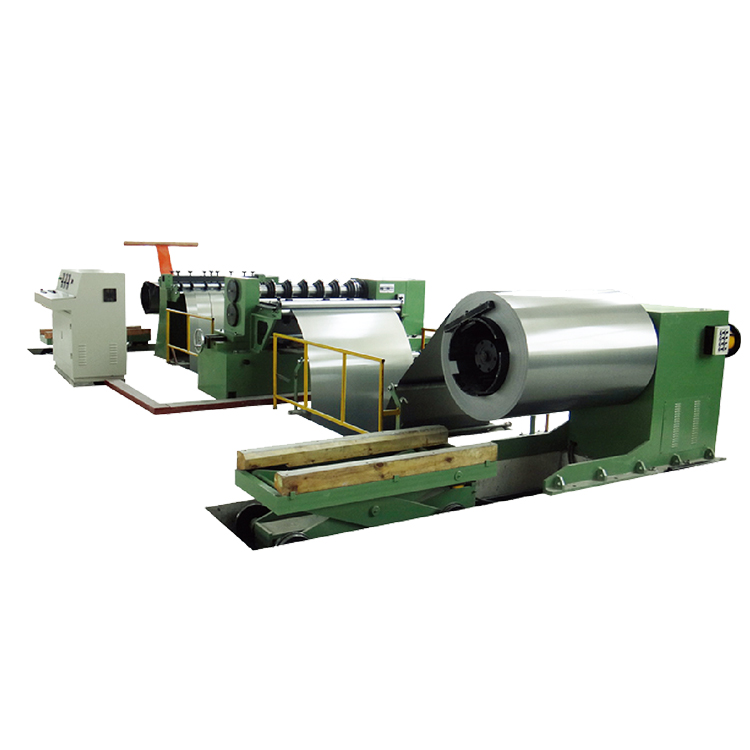

OEM Factory for Reactor Disk Core Cutting Line - Silicon Steel CNC Automatic Transformer Core Lamination Servo Motor Cut to Length Line – Trihope Detail:

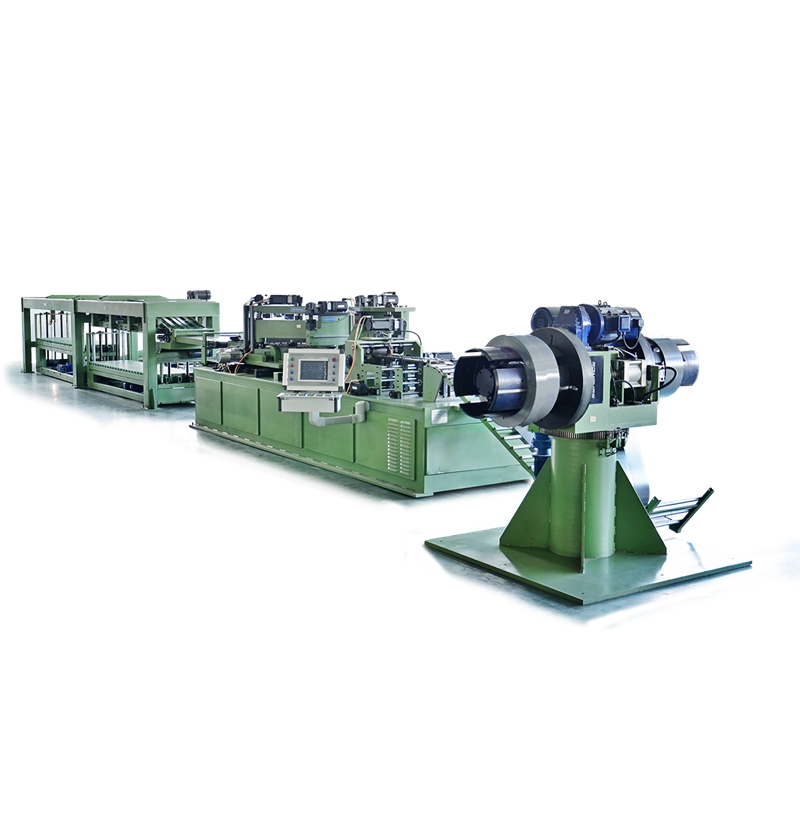

The transformer shear production line adopts multiple sets of AC servo system. Respectively used in: material transmission channel by servo motor to set material width in screen operation and automatic positioning. Shearing and v-notching adopt AC servo motor as driving power, with fast response speed, low noise, small vibration, convenience maintenance.

Features

Frequency speed decoiler, automatic tracking system.

Electrical control double loading , Easy position Replacement.

No need pit for Material Storage Device, Ensure safe and convenient.

PLC Control, Servo adjust width, Servo feed

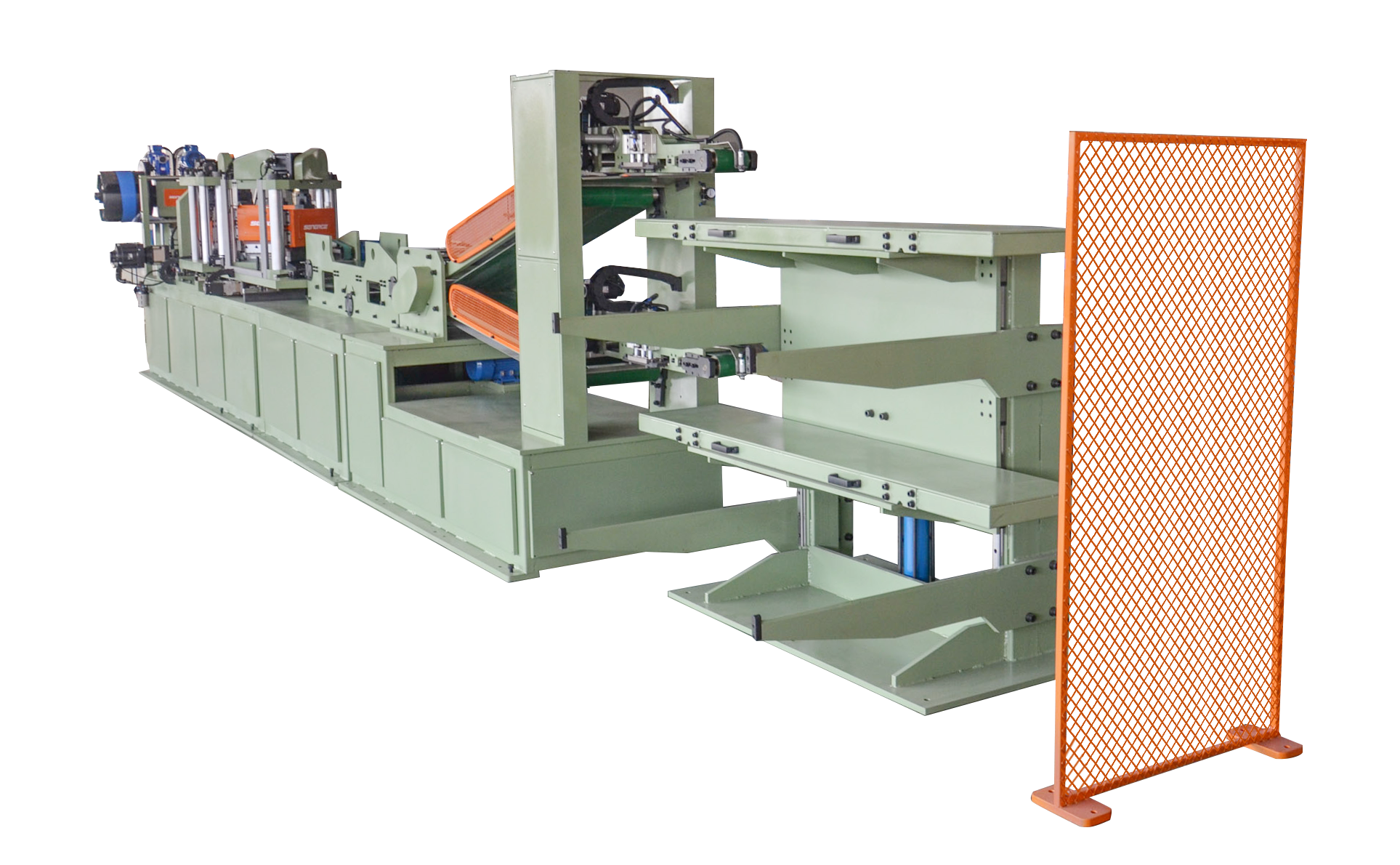

V notching, Hole punching, Shearing device kinds of collocation, meet all kinds of needs

Automatic depiler , stacking neatly

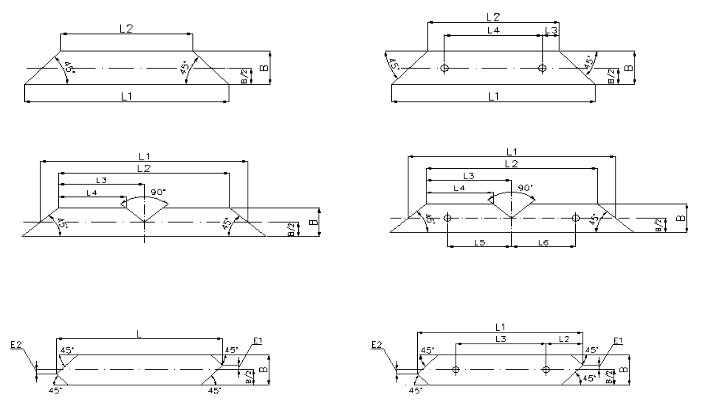

Core type by transformer core lamination machine

Two shear one punch

Two shear two punch

Two-shear Two-punch Central Positioning Stepping

Technical parameter

| Transformer Core Cutting Machine | ||||

| Equipment model | HJ-300 | HJ-400 | HJ-600 | |

| Processing range | Sheet Length (mm) | 400–1800 | 400–2200 | 400–3500 |

| Sheet Width (mm) | 40–300 | 50–400 | 60–600 | |

| Thickness of sheet(mm) | 0.23–0.35 | |||

| Process precision | Tolerance of length(mm) | ≤±0.15 | ||

| Shearing angle | ±0.025º | |||

| Shearing burr(mm) | ≤0.02 | |||

| Coil specification | Tolerance of width(mm) | ≤±0.1 | ||

| Burr(mm) | ≤0.03 | |||

| Tolerance of S(mm/2m) | ≤0.2 | |||

| Feeding speed(m/min) | 0–180 | 0–200 | 0–200 | |

| Shear efficiency | Width 160mm,With a v-notch yoke L1 length 800 mm ,Side leg L1 length 600 mm ,Shear combination, more than or equal 36 times per minute | Width 200mm,With a v-notch yoke L1 length 1000 mm ,Side length L1 length 800 mm ,Shear combination, more than or equal to 30 times per minute . | Width 200mm,With a v-notch yoke L1 length 1000 mm ,Side length L1 length 800 mm ,Shear combination, more than or equal to 36 times per minute. | |

| De-coiler | Quantity | Double head | ||

| Max.loading /single head (kg) | 1500 | 1800 | 2000 | |

| Coil innner dia mm | Φ500 | |||

| Max coil outer dia mm | Φ1000 | |||

| Docoiler speed m/min | 0–180 adjustable | |||

| Expanding range mm | Φ480–Φ520 | Φ480–Φ520 | Φ480–Φ520 | |

| Buffer device | no pit | |||

| Feeding form | Single servo feeding | Single servo feeding | Double servo feeding | |

| V-notching | Notching arrange(mm) | ±25 | ±25 | ±35 |

| Steplap | 7 steps | |||

| Punching device | without | 1 unit | 1 unit | |

| Shearing device | 2 unit(45º&135º each have one unit ) | |||

| Depiler | Devide material up and down, stacking | |||

| Total Powerkw | 25 | 30 | 45 | |

| Power supply | 380V±10% 50Hz (Or Customized) | |||

Product detail pictures:

Related Product Guide:

OEM Factory for Reactor Disk Core Cutting Line - Silicon Steel CNC Automatic Transformer Core Lamination Servo Motor Cut to Length Line – Trihope , The product will supply to all over the world, such as: , , ,

By from -

By from -

By from -

By from -

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com