Factory Supply Copper Wire Wrapping Machine - Hydraulic drawing machine for copper bar – Trihope Detail:

Process flow of Hydraulic drawing machine

Copper bar head sharping → unreeling → straighten and conveying → clamping → lubricating → drawing → saw cutting →lateral movement → roll conveying → saw cutting with fixed length → roll conveying to the storage table.

Main Body of Drawing Machine: The main body (bed) of the drawing machine is equipped with guide rails, which is used for reciprocating motion of fixed drawing head in the drawing process and will not deform when it is subjected to tension.

Mainframe of Drawing Machine

Copper Rod Rack: This rack for Hydraulic drawing machine is made of profiled steel through welding. On its bottom are mounted the pulleys that can reciprocate crosswise according to the width and speed of copper strips, which can ensure that the copper strips are at the central position when entering the straightener. Its load-bearing capacity is 5000kg.

Mobile Rack

Straightening Feeder for drawing machine for copper bar: It is made of steel plate through welding. It is equipped with the longitudinal and transverse rollers to adjust the gap by hand wheel and straighten the blank so as to prevent the bent blank from entering the drawing die.

Copper Bar Straightener

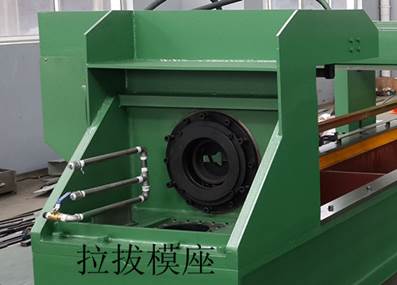

Drawing Die Holder of drawing machine for copper bar: This die holder is used for placement of die. The position of the die holder can be required to be adjusted according to the curvature of both sides of the finished product after drawing to guarantee the quality of finished products. The special oil tank and pump can be used to form the oil curtain to guarantee the lubrication of die.

Drawing Die Holder

Hydraulic System: The hydraulic system of copper bar drawing machine includes Hydraulic Station and drawing oil cylinder. The Hydraulic Station employs the removable (logical) valve to guarantee the stability of use process. The oil pump consists of main pump and auxiliary pump to make drawing and resetting with different speeds so as to improve production efficiency. The hydraulic cylinder is made of overall seamless steel pipe through machining and the drawing length can be set at random.

Hydraulic Oil Cylinder of Drawing Machine

Cutting Mechanism: The cutting mechanism of Hydraulic drawing machine is fixed at the rear of the die holder and uses the saw blade for cutting. It can automatically complete cutting the blank and resetting after the drawing length is set.

Cutting Mechanism

Drawing Head for Hydraulic drawing machine: It is fixed at the front of the hydraulic rod. It realizes clamping and loosening according to the pneumatic principle. The fixtures can be changed to draw the flat and cylindrical blanks.

Drawing Head

Transfer Mechanism for copper bar hydraulic drawing machine: The mechanism is used to convey the after-cut finished products crosswise to the transfer roll table for entry into the next procedure. It can carry out pneumatic clamping, electric motion and automatic resetting.

Transfer Mechanism

Roll Table for Hydraulic drawing machine: It is used for the transport of finished products.

Transfer Roll Table

Cutter for Hydraulic drawing machine: It is used for the fixed-scale cutting of finished products. It cuts the finished products with the saw blade by hydraulic locking and collects the copper scrap with the recycling bin.

Product detail pictures:

Related Product Guide:

Factory Supply Copper Wire Wrapping Machine - Hydraulic drawing machine for copper bar – Trihope , The product will supply to all over the world, such as: , , ,

By from -

By from -

By from -

By from -

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com